Modeling and Simulation of Metal Additive Manufacturing Processes Across Scales

The Additive Manufacturing Simulation Group

In 2016, Christoph Meier established the Additive Manufacturing Simulation Group at the Institute for Computational Mechanics at TUM. Meanwhile, the AMSim Group consists of two postdoctoral researches (Christoph Meier and Magdalena Schreter) and of four Ph.D. students (Sebastian Pröll, Patrick Praegla, Nils Much and Reimar Weissbach). Starting in January 2024, three further Ph.D. students and one additional postdoc will join the group, funded through the ERC Starting Grant project "Accelerated Additive Manufacturing: Digital Discovery of a New Process Generation (ExcelAM)", recently raised by Christoph Meier.

Research Mission

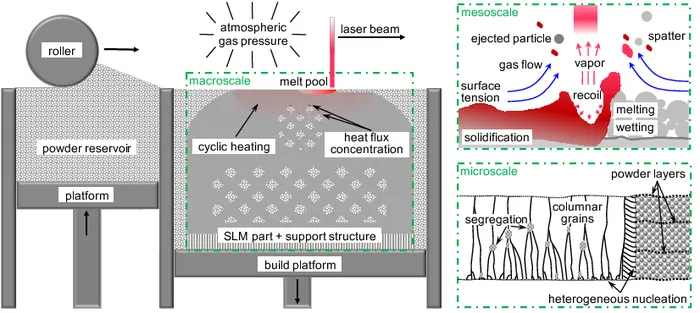

Additive Manufacturing (AM) processes for metals such as Laser Powder Bed Fusion (LPBF) have the potential to revolutionize product development and design as well as the structure of future supply chains. However, since the underlying physics are not well understood, their potential can not be fully exploited at presence. Sub-optimal process conditions lead to severe defects on different scales, rendering parts unsuitable for use. Critically, known regimes of stable processing go along with very low built rates, i.e., very high costs compared to other processes. This limits LPBF to selected high value applications such as medical devices but prohibits applications in mass production where it otherwise could allow for entirely new technologies.

By modeling the different length scales governing these processes, we aim to gain fundamental understanding of the underlying physics and, eventually, to inspire new process strategies overcoming the short comings of existing processes. In particular, our overall approach considers the modeling of metal powders and powder spreading processes, meltpool modeling, part-scale modeling and microstructure modeling in metal additive manufacturing (see, Meier et al. 2017, Meier et al. 2021). While the main focus lies on LPBF, we have shown in our recent publication (Fuchs et al. 2022) that many of the developed modeling and simulation approaches can be transferred to other AM processes such as Binder Jetting (BJ), Directed Energy Deposition (DED) and Material Jetting (MJ).

Publications

Please find publications on this topic here.