Machine learning-based agent model, Computational fluid dynamic (CFD), Artificial intelligence-aided design of gas turbine cooling structures

Supervisor | Subject |

|---|---|

| Prof. Dr. Dongsheng Wen | Machine Learning, Conditional Generative Adversarial Network, Film Cooling |

Editor | Cooperation/Funding |

| Li, Zuobiao; M.Sc. | This project is supported by the China Scholarship Council, whose support is gratefully acknowledged. |

Moitvation

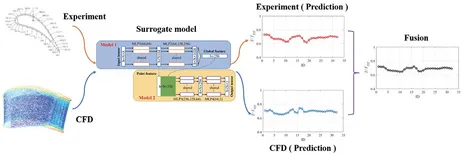

At present, with big data and intelligent algorithms as the core driving force, the entire engine industry chain is being propelled towards digitalization, intelligence, and integration trends. Based on the integration of vast industrial design data and domain knowledge, it is feasible to develop surrogate models for fast prediction of performance and multi-physics fields in core cooling units. Moreover, by leveraging various state-of-the-art optimization algorithms such as genetic programming and reinforcement learning, an advanced design optimization platform can be established specifically tailored for gas turbine cooling structures.

Although general artificial intelligence, exemplified by ChatGPT, is sparking a new wave of technological revolution, there remain numerous unresolved challenges to effectively apply it in the field of gas turbine design. We encapsulate these challenges as follows: the database, surrogate models, and design/optimization platform.

Reliable data constitutes a valuable asset, yet historical data accumulated over decades in the industrial domain often exhibits variances in terms of data structure, data accuracy, and data scale. Therefore, it becomes imperative to perform data cleansing, summarization, storage, and standardized representation, while automating these processes, as essential endeavors towards the establishment of a database.

The challenges faced by surrogate models, serving as the bridge between data and design platforms, present a notably intricate landscape. Firstly, the integration of data-driven and physics-informed approaches becomes crucial to yield predictions that possess enhanced physical significance. However, the inherent complexity of physical equations renders this task far from straightforward. Secondly, as previously highlighted, data exhibits remarkable diversity, demanding the development of surrogate models capable of effectively harnessing data with disparate levels of precision, distinctive structures, and varying scales, such as the utilization of variable-precision networks. Furthermore, the scarcity of high-precision data necessitates thoughtful consideration of training strategies tailored to handle small-sample scenarios.

Regarding the optimization module, numerous mature and reliable optimization algorithms, such as the adjoint method and genetic programming, have already been developed. Our research endeavors involve exploring the feasibility of reinforcement learning, which served as a core driving force behind the previous breakthrough of AlphaGo, within the realm of cooling structure design.

Project Goals

The undertaken research primarily involves three main components: (1) establishing an extensive and reliable database; (2) devising appropriate designs for neural network structures, activation functions, loss functions, etc., to construct surrogate models with sufficient accuracy to meet the requirements of industrial design; (3) exploring the feasibility and effectiveness of integrating surrogate models with optimization algorithms.

Method description

We have successfully employed Conditional Generative Adversarial Networks (CGANs) to develop a dimensionless temperature distribution prediction model for arranging multiple rows of cylindrical cooling holes on a flat plate.

References

[1] Li, Z., Su, L., Wen, F., et al. Deep learning method for fast prediction of film cooling performance. Physics of Fluids, 34(4), 2022, pp. 047111.

[2] Zhi, R., Li, Z., Wen, F., et al. Research on Performance Predictions using Single-hole Film Cooling Based on PointNet. Physics of Fluids, 35(2), 2023, pp. 025108.

[3] Wen, F., Li, Z., Wan, C., et al. Cost reduction for data acquisition based on data fusion: Reconstructing the surface temperature of a turbine blade. Physics of Fluids, 35(1), 2023, pp. 016110.