Content

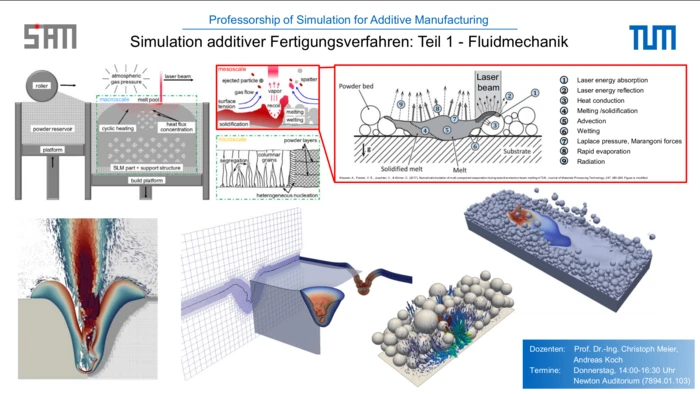

The lecture focuses on state-of-the-art approaches in physics-based modeling and simulation of additive manufacturing processes and establishes a close connection to current research activities in this field. The emphasis is on modeling fluid mechanical aspects (e.g., melt pool and evaporation dynamics in powder bed-based laser melting) in metal additive manufacturing. The course begins with an overview of the various classes of additive manufacturing processes. This is followed by an introduction to the underlying physical mechanisms as well as the key fluid mechanical aspects (e.g., the influence of surface tension, wetting, and (non-equilibrium) evaporation dynamics). Current modeling approaches are presented, the resulting model equations are derived, and the application scope, transferability, and limitations of these models are discussed in detail. In the further course of the lecture, various approaches for the discretization and numerical solution of these model equations (e.g., numerical methods for describing interfaces in multiphase flows) are introduced. In addition to mathematical properties of the presented solution methods, the discussion also focuses on application-relevant topics such as prediction accuracy, computational cost, and the integration of experimental process data. Furthermore, it is demonstrated how modern modeling and simulation methods can contribute to the identification, prediction, and targeted reduction of typical defects in metal additive manufacturing (e.g., Rayleigh–Plateau or keyhole instabilities). The relevant modeling and discretization approaches are presented in a broader context and are not limited to additive manufacturing processes. This ensures that the knowledge imparted can be transferred to more general problems in computer-based thermofluid dynamics (e.g., multiphase flow with phase change).