Influence of the Flow Distribution on the Mixture Behavior in Multi-Injector Burner Systems

Supervisor | Subject |

|---|---|

Editor | Cooperation/Funding |

| Fabian Marquez Macias, M.Sc. | This project is funded by SIEMENS and BMWi, whose support is gratefully acknowledged. |

Motivation

Combined gas and steam power plants are a key technology for stabilization of the electrical power supply with a high contribution of regenerative energy sources. The use of regenerative fuels at full and part-load conditions is of particular importance for compensation of the intermittent electrical power output from renewable energy plants.

To increase the efficiency of gas power plants, the outlet temperature of the exhaust gases from the combustion chamber must be increased. Since NOx emissions rise with flame temperature, residence time of the exhaust gases must be reduced in order to meet the emission limits.

A reduction of the residence time can be achieved by the use of multi-injector jet burners instead of the large swirl burners representing the state of the art (Fig. 1). High temporal and spatial mixture homogeneity of air and fuel downstream of the injectors is essential for achieving minimum NOx emission. This depends on the proper design of the upstream flow path and particularly of the flow reversal section, which determinates the flow split among all injectors and the steadiness in the entrance region of the injectors, where the fuel is injected.

The research aims at determining the influence of the geometrical parameters of the flow reversal section and the air inflow conditions on the flow distribution and stability as well as the fuel-air mixture quality. From the experimental results a linear model shall be derived, which can be used as engine combustor design tool in view of improved mixture quality and reduced flow inhomogeneity and intermittency. For that purpose, the POD method (Proper Orthogonal Decomposition) shall be used. It allows the representation of high non-linear problems as a linear function of eigenvectors describing the influence of each mean input variable.

Experimental Setup

The flow homogeneity and the mixture quality downstream of the injectors are investigated in the water channel test-rig for different multi-injector burner designs (Fig. 2).

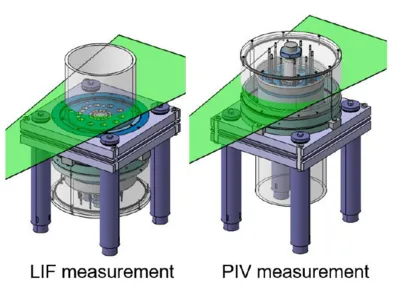

An adapted burner model was designed for water channel measurements in this project. This model has two optical accesses at the burner head and the combustion chamber for flow and mixture visualisation (Fig. 3). Due to the modular construction design, the influence of different geometrical parameters can be studied.

The flow and mixture investigations are performed by using the methods of PIV (Particle Image Velocimetry) and LIF (Laser Induced Fluorescence). The air and the fuel flows are both simulated by using water, because the effects originating from the temperature ratio and the different molecular mass compensate each other. Moreover, the global flow distribution will be measured with hot-wire anemometers, which are integrated in the burner model.

Open Work Packages

After initial operation of the test-rig, the flow fields upstream of the injectors and the mixture downstream on the combustion chamber will be measured for the generic geometry. The measurements will be complemented by CFD studies on the influence of geometrical parameters of the flow reversal section.

Based on these CFD results, the applicability of the POD method for achieving the described research goals shall be studied. Subsequently, two new burner models based on the generic geometry will be measured for providing a linear model based on measured data of the flow inhomogeneity and mixture quality.